Being strong and hard, they help to ease friction, and thereby, wear and tear amongst the mechanical parts. The advantages of jewel bearings include accuracy, small size and weight, predictable friction, good temperature stability, and the ability to operate over the course of decades, as they don't break down.

These rubies are synthetically developed utilizing aluminum and chromium oxide that undergoes a series of heating, fusing and crystallizing processes. Because the material is mass-produced, it does not have the extremely high intrinsic value of natural rubies. The number of rubies used in a mechanical watch varies depending on the complexity of the movement. The more moving parts there are, the more rubies are used. A typical fully jeweled time-only watch has 17 jewels, but some watches can utilize many more.

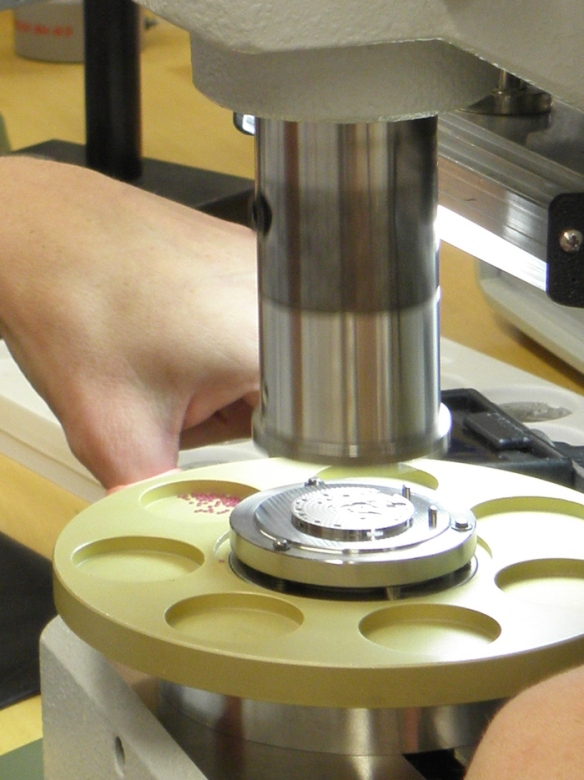

Setting the minuscule rubies into the designated movement holes is a tedious task, done using tweezers and microscopes.

When a mechanical watch offers a skeleton movement, or has a

transparent sapphire caseback for viewing the movement, the rubies are

an entrancing portion of the design.

Today, some top luxury brands are utilizing silicium parts to reduce

friction, as well as reduce the need for too-frequent servicing of

watches. vedere di piu rolex imitazione e Hermes Classic

Setting the minuscule rubies into the designated movement holes is a tedious task, done using tweezers and microscopes.

When a mechanical watch offers a skeleton movement, or has a

transparent sapphire caseback for viewing the movement, the rubies are

an entrancing portion of the design.

Today, some top luxury brands are utilizing silicium parts to reduce

friction, as well as reduce the need for too-frequent servicing of

watches. vedere di piu rolex imitazione e Hermes Classic

没有评论:

发表评论